From Functional to User-Friendly: Humanoid Robot Actuators Determine Performance and Shape the Future

Date:2025-12-08When we marvel at a humanoid robot's fluid dance steps or precise threading of a needle, our attention often focuses on its advanced "brain" algorithms or sharp "eye" vision. However, the unsung heroes translating these digital commands into elegant physical motions are the actuators embedded within its metallic frame. They serve as the robot's "motion hubs," connecting and driving various components to achieve seamless movement. Based on mechanical engineering principles, actuators are critical for converting electrical energy into mechanical motion while ensuring precise control and stability, directly impacting the accuracy and reliability of actions.

In the overall architecture of humanoid robots, actuators are core components, with their importance manifested in the following key areas:

Cost Core: High Proportion in Overall Machine Cost

Actuators often constitute the primary hardware cost in humanoid robots. A full-size humanoid robot typically features dozens of degrees of freedom (DoF), with each DoF relying on an actuator. For example, Tesla's Optimus incorporates over 28 rotary and linear actuators in its body, plus additional miniature actuators in its dexterous hands. According to supply chain analysis from current humanoid robot companies, in high-configuration models (e.g., those with multi-fingered dexterous hands), actuator costs may account for 30% to 50% or more of the total bill of materials (BOM). In simplified versions, this ratio can exceed 60%. The cost control and supply stability of actuators directly determine whether humanoid robots can achieve scalable deployment.

Performance Determinant: From Basic Motion to Precise Control

Actuators do not merely enable robots to "move"; they are key to making them "user-friendly." They directly influence three major performance metrics: motion precision, response speed, and stability, affecting the smoothness, accuracy, and dynamic response of humanoid robot movements.

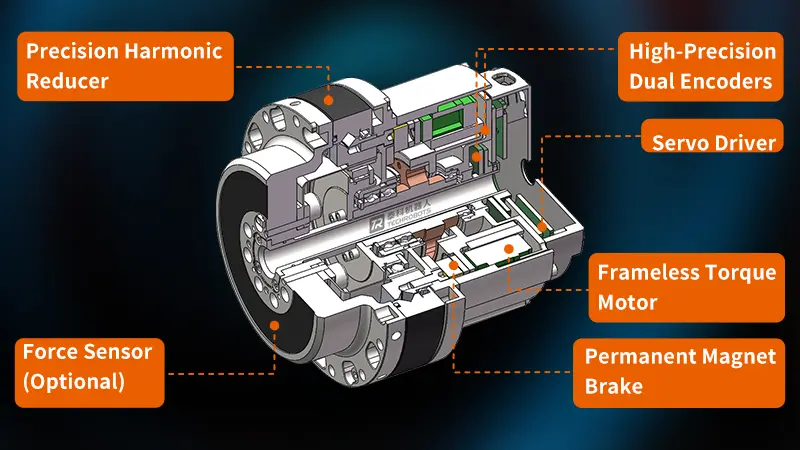

From a physics perspective, actuator performance hinges on torque density (torque output per unit mass) and power density (power output per unit volume). This is akin to human muscles: sufficient strength without excessive bulk to avoid clumsiness due to self-weight. High-performance modules can achieve sub-60 arcsec repeatability through integrated high-resolution encoders, enabling stable tasks like smartphone chip soldering or microelectronic assembly.

In terms of response speed, advanced modules employ closed-loop control systems with millisecond-level latency. This is based on feedback control theory: sensors monitor position and velocity in real time, while controllers adjust motor output to minimize errors and ensure dynamic stability. For stability, modules require high rigidity and low backlash to suppress vibrations. Per vibration dynamics principles, excessive backlash can amplify resonance and increase jitter risk. Premium modules reduce backlash to under 20 arcsec via precision gear designs (e.g., harmonic reducers), preventing robot jitter, instability, or falls. In summary, these metrics directly influence overall reliability and safety.

Additionally, actuator reliability is paramount, as a single failure could lead to system-wide functional loss or safety incidents.

Differentiated Design: Varying Needs for Different Positions

Requirements for actuators vary significantly across robot positions, primarily in three aspects:

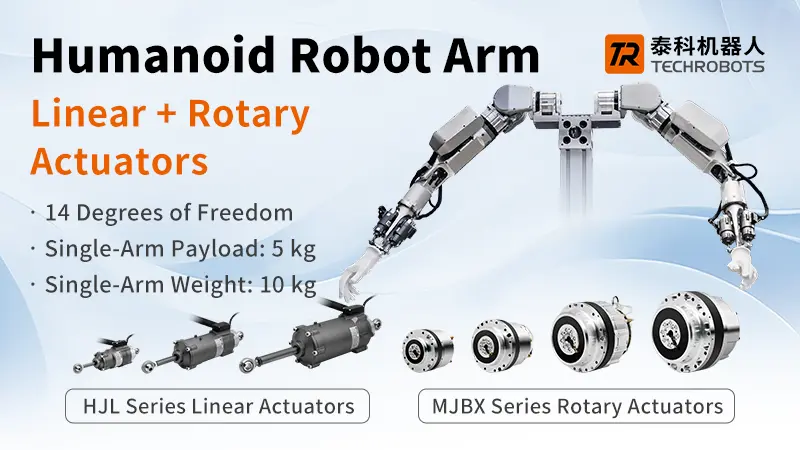

Load Requirements: Lower-limb actuators must support full body weight, with torque demands often exceeding hundreds of N·m; upper-limb actuators prioritize flexibility, typically requiring tens of N·m.

Size Constraints: Wrist and hand actuators, due to limited space, must be highly compact, with diameters often under 60 mm; hip and shoulder actuators have more lenient space allowances.

Functional Focus: Actuators for locomotion emphasize high rigidity and fatigue resistance to handle repetitive impacts; those for manipulation prioritize smooth motion, precision, and sensitivity, using low-friction bearings to minimize energy loss.

This differentiation hinders full standardization of actuators, necessitating position-specific optimization and serialization. However, modular platforms (e.g., standardized interfaces) can balance flexibility and cost.

Technical Challenges: Balancing Miniaturization and High Performance

While humanoid robot actuators share structural similarities with those in collaborative robots, the former face more stringent performance demands, with lightweighting and miniaturization as primary goals—thus favoring high-torque-density actuators.

A major development challenge is balancing "miniaturization" with "high torque." Per thermodynamics and materials science principles, lightweight designs rely on high-strength materials like aluminum alloys or composites, while optimizing thermal management to prevent motor overheating. Robot actuators must integrate core components—motors, drivers, reducers, sensors, brakes, and encoders—into compact spaces, where volume reduction increases thermal density and energy consumption. Low power consumption is critical, with efficient servo drivers boosting energy conversion efficiency to over 90%, extending battery life.

Another challenge is dynamic response. In rapid motions, modules must deliver peak torque while maintaining control precision. This relies on control engineering's PID algorithms (proportional-integral-derivative), adjusting in real time to counter disturbances like uneven terrain or load changes. Early markets lacked standardized products, prompting many vendors to self-develop modules. With technological advances, suppliers now offer integrated solutions supporting customization for diverse needs.

Techrobots, with its proprietary servo drivers (efficiency up to 95%), has built a full-stack solution since 2024 encompassing humanoid robot actuators, hardware bodies, and core components. It provides customized development and delivery of full force-controlled upper/lower limbs and complete accessory kits, currently accelerating mass production to fit various embodied intelligence scenarios.

Technological Evolution: Hardware Beyond Standalone Components

Reviewing the evolution of humanoid robots, the history of actuators is a relentless pursuit of higher performance, smaller size, and lower cost. Current diverse technical paths reflect the industry's proactive exploration of future applications.

As a general-purpose platform, humanoid robots hold immense potential, but identifying scenarios for efficient, reliable scalability requires further validation. This directly affects actuator technology selection: For upper-limb actuators, harmonic reducers are mainstream, but cycloidal and quasi-direct-drive solutions remain competitive; lower-limb actuators see contention among harmonic, planetary, RV rotary options, and screw-based linear modules. In sensing, "multi-sensor fusion" is consensus, but optimal sensor combinations and fusion algorithms for varying tasks remain exploratory.

The diversity of technical paths highlights industry innovation while demanding flexible strategies from supply chain players, with increased R&D and scenario validation investments. Future mainstream routes will hinge on breakthrough scenarios: Consumer breakthroughs emphasize safety, low noise, cost, and human-machine interaction; industrial adoption prioritizes payload, efficiency, precision, and long-term reliability. Thus, hardware requires ongoing validation through commercial deployments to form consensus and standards, essential for scaling humanoid robot applications. As a manufacturer advancing both "standardized + customized" development and production, Techrobots remains a collaborative partner in problem-solving, continually progressing alongside industry and market advancements.

Previous Article: None

Next Article: Key Technical Factors for Selecting High-Performance Humanoid Robot Actuators