Explore the two major directions of co-robots in the future

Date:2020-12-041. The application of domestic industrial robots will be more sophisticated.

The electronics industry is now the second-largest application field after automobiles. Since 2017, the number of co-robots used in the electronics industry has been increasing rapidly. Due to rapid product upgrades, the 3C industry has relatively high requirements for flexibility, accuracy, and speed. Compared with other industries, the proportion of manual participation is the highest. Current robots cannot fully meet market needs in terms of speed or functionality.

Domestic industrial robots continue to be researched and polished in the electronics industry, and they have made significant progress in the field of hand-eye combination, and are becoming more and more precise in operations such as fitting, precision assembly, and dispensing. In the past, industrial robots were dominated by the automobile industry, and many related products depended on the automobile industry to survive. China has concentrated 70% of the global production capacity of 3C products. As China's 3C industry continues to demand industrial robots, it is believed that China's 3C industry will also widely use China's robot brands.

The 3C industry is changing with each passing day, with many and small parts. The precision of the robot hand is far from meeting the needs of precision assembly and testing. Therefore, multi-joint robots need to be more intelligent. The current development direction is miniaturization, refinement, and speed. To become truly intelligent, industrial robots must start from a stand-alone machine to an overall solution and toolkit, and comprehensively improve the overall application scheme of industrial robots. Only in this way can my country's industrial robots continue to develop in more industries.

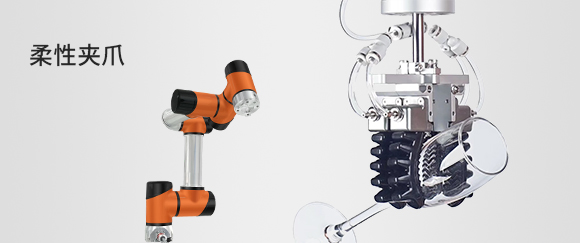

2. The co-robot market is booming, and EOAT will have a bigger market.

Co-robots realize flexible production requirements through human-machine collaboration, and can better adapt to many small and medium-sized application scenarios. Many companies have problems such as transformation and upgrading and limited production lines. Now companies are beginning to pay attention to co-robots. Changes in social needs make companies pay more attention to practical applications instead of the focus on robots themselves.

The flexibility of co-robots comes from EOAT, also known as end-of-manipulator tools, including grippers, sensors, rapid tool change devices, and visual control systems. EOAT is very important to co-robots. It is the front-end application of co-robots and is also lightweight. The basis of flexible production, with the continuous increase of manufacturers' demand for robot applications, flexible end tools have become the key to enterprise optimization investment.

At present, China’s EOAT market is facing the problem of integration. Although there are many component manufacturers, they do not have unified bargaining power. Therefore, domestic manufacturers have very low profits, a wide variety of workpieces, and small batches. Factory production is often one machine, high Performance EOAT products are relatively few. The scattered and diverse EOAT suppliers in the market require engineers to learn the programming methods of different parts according to the characteristics of the parts, thereby increasing the difficulty of market integration for integrators, resulting in low procurement efficiency and high costs; due to the high frequency of EOAT replacement and production efficiency Low, difficult to quickly adapt to the production line.

In the Chinese market, the success of co-robots has brought about the development direction of robots, and many co-robot manufacturers have made remarkable achievements under their technological advantages.

Previous Article: Application Scenarios of High-Load Collaborative Robots

Next Article: Which work scenarios are more suitable for deploying co-robots?